Rapid Prototyping of NEw Scientific ToOls

Scientific Prototyping. Vienna Scientific Instruments supports and accelerates innovative scientific research through rapid prototyping of novel scientific instruments and tools for life sciences and related disciplines. Prototypes are key to the development of a product or measurement method/scientific instrument, helping to develop the structure, function and appearance of your solution. They are also invaluable for obtaining feedback from users, such as students and technical staff. Designers often make several prototypes during the development of a product. Sometimes the first prototype is made early in the design process from readily available materials such as paper, cardboard, and even found objects. Later, designers may use construction kits for easy prototyping - the parts are easy to put together, but also easy to take apart. At a certain stage, however, there is no alternative to building a large engineering prototype that matches the final product in form and function - allowing scientists, engineers and designers to confirm performance and usability before going into production, or to make changes. Once successful, it can be used as a model for full-scale commercial production or to make the designs available to the general public (e.g. as open hardware). In brief, rapid prototyping can be used to advance science in several ways, including:

- Faster iterations: Rapid prototyping allows scientists to quickly iterate and test ideas. They can create multiple prototypes in a short period of time and test them under real-world conditions. This process helps refine ideas and improve the accuracy and efficiency of research.

- Customized solutions: Rapid prototyping enables the creation of customized solutions to specific research problems. Scientists can design and build prototypes tailored to their specific needs, allowing them to quickly test ideas and working principles.

- Reduced costs: Rapid prototyping can reduce the costs associated with scientific research. It allows scientists to create prototypes without expensive tools or equipment.

- Collaboration: Rapid prototyping can facilitate collaboration between scientists, and facilitate cross-sectoral collaboration. Researchers and engineers can share their ideas and designs and work together to create prototypes. This process can lead to more efficient and effective research instrumentation - solving complex problems.

Overall, rapid scientific prototyping can be an extremely valuable tool for advancing science, allowing researchers to quickly and cost-effectively test their ideas, refine their designs, and collaborate with others in the field or across disciplines.

A great solution? Lets prototype it with help by Vienna Scientific!

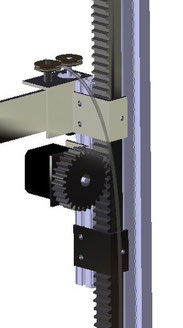

Experienced mechanical, electronic and software engineers at Vienna Scientific Instruments will CAD design your solutions and assist in the detailed planning of your scientific prototype - both on a technical and budgetary level. Non-disclosure agreements are available upon request. Our extensive in-house machine shop (including various technologies of 3D printing, CNC milling and laser beam cutting, casting of non-ferrous metals, resins and ceramics) processes various materials for prototype production, and we will source all necessary components (sensors, microcontrollers, etc.) according to your specifications (and our experience). In particular, our 3D printing facilities allow rapid prototyping and thus a competitive price/performance ratio. Finally, the functioning of the technical prototype can be tested in a controlled environment (-20° to +50°C, 10-90% rH depending on the temperature) with partner organizations. Contact us to discuss your prototyping ideas.