Tray and Rack Systems for Mass Rearing of Mosquitoes

The requirement for efficient insect mass rearing and especially mosquito mass rearing technology has been one of the major obstacles preventing the large scale application of the Sterile Insect Technique (SIT) against mosquitoes and other insect pests. Balestrino et al. (2012, 2014) developed and evaluated a larval rearing unit (see literature below) to successfully rear hundred thousands of larvae to pupae per mosquito rack.

Mosquito Mass Rearing Racks & Modules

Mosquito Tray and Rack Rearing System, efficiently holding 30 mosquito larvae rearing trays (standard configuration; IR-MMR-TR30) with developing larvae for medium- to large-scale mass production. The rearing unit is simple to use, maintains minimal water temperature variation and negligible water evaporation (due to closely stacked trays) and allows normal larval development in the special trays that mimic the mosquito rearing environment. Trays can be automatically (electric gearbox, 24 V) or manually tilted for efficient collection and cleaning purposes, a stainless steel collection system for the overflow (with sieves / collection containers for pupae and a tank for the water) is available. The close stacking of the trays in the rack and the possibility of combining several racks (in modules) makes this mosquito rearing unit a valid solution for maximum use of space - thus reducing construction, heating and cooling costs. Up to four racks can be combined as a module (see below), operated by a tilt control unit (separately controlled for each rack). XL Rearing Racks holding 50 trays are available as an option (IR-MMR-TR50; see below). The racks require minimal maintenance and labour costs can be further reduced by combining the Mosquito Tray & Rack System with the optional IR-401 / IR-402 automatic larvae liquid feeding station IR-401 / IR-402.

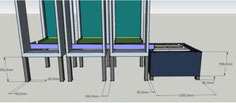

- Mosquito T&R Modules. For the most efficient larval mass rearing setup, Mosquito racks are combined into functional rearing units (modules). Modules of 2, 3 (see illustration) or 4 racks are available (see Model/Types below). In particular, modules are more space efficient than single racks because less of the rearing facility's floor area needs to be left open for pupal/larvae collection/water tank positioning during pupae harvesting. Continue reading

-

Modules share: Electrical tilting control unit, 1 common collection channel (removeable) for larvae/pupae and effluent when tilted ("harvested") per 2-4 racks, effluent collection tank with 2 sieves / collection baskets for larvae/pupae. The drawing above shows a module of 3x TR30 racks ("IR-MMR-TR30-M3"; see Model/Types for all product variants), with collection areas per rack (green; back, bottom) leading the effluent (water, mosquito pupae, remaining larvae) from the tilted rearing trays to a common collection channel (purple) and then to the sieves / collection baskets (gray) on top of the effluent collection tank (dark blue). One "collection unit" (sieves, tank) can be used to operate multiple modules. Please note that the shared collection channel and electrical cables (for the automatic tilting mechanism) must be removed/disconnected before the racks can be moved independently (e.g. if they are placed on wheels).

Mosquito Mass Rearing Racks - features

- Durable, stainless aluminium racks - virtually maintenance free

- Automatic tilt, manual operation in case of power failure

- Space optimized, tight stacking of trays

- Minimized water loss, homogeneous rearing conditions

- Labour efficient operation (tray top filling with water, etc.)

Options:

- Collection system (effluent tank, high volume baskets/sieves)

- Maxi Racks (50 Trays, for rearing facilities with limited floor space)

- Rearing modules, further optimising space and operation

- Automated feed application with dedicated IR-401 / IR402

| Specifications | Mosquito Mass Rearing Rack TR30, TR50 | OPEN |

|

Specifications for one TR30 Rack

Optional:

Optional:

|

||

| Models/Types |

Mosquito Mass Rearing Racks / Module Configurations |

OPEN | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| References | Mosquito Mass Rearing Racks | OPEN |

|

||

Rack operation: Tilt gently, harvest thoroughly, reuse carefully

After mosquito rearing tray preparation, first pupation is usually recorded at day 6 from L1 introduction, effective harvest time at local facilities need to be established and will depend on environmental conditions, feed etc.

In any case, the automatic electrical system of the Tray & Rack Rearing Unit (or Module) is used for tilting. Up and down buttons (of the respective rack) allow for gentle and easy operation. As a fallback option in case of power cuts, use the manual jack (per unit) to slowly create a gradually increasing slope that will pour the water out of the trays towards the collection area (in the back).

- Continue reading on how to operate the racks ...

-

Care should be taken not to tilt the trays too fast (manually) to prevent water containing larvae and pupae from spilling out. Since the standard rack holds a total of approximately 150-180 L (for 30 trays) of water when fully loaded, collection should be done slowly in batches of approximately 30-40 L per tilt into the large 200-µm screen baskets / sieves (placed on top of the collection tank). Parts of the collected water can be retained for washing trays, and rearing remaining larvae (after size-based sorting).

Pour/rinse the water from the collection basket into an external ~300-μm sieve to concentrate the larvae and pupae and discard the debris, and finally transfer them to small trays with 1-2 L of osmosis water / collected effluent. Continue tilting until all the water has been drained from one rack. Some larvae and pupae will remain on the inner edges of the rearing trays and must be washed off for collection (e.g. with some of the retained water); alternatively, water hoses with spray nozzles are used for rapid rinsing of the trays (if low salinity, Cl-free tap water is available). Continue to harvest the other racks per rearing module (if available); racks are individually tiltable (automatically and manually). The larval rearing water collected in the mobile tank can be reused for rearing the remaining mosquito larvae after pupation; potentially supplement with some fresh water. However, performing more than one tilting/sorting event can be be considered a trade-off between pupae production, female pupal contamination and cost efficiency (FAO/IAEA, 2020). Continue reading on size separation of larvae, male and female pupae ...

OPEN FOR R&D - Advanced, fully Automated TRAY & RACK Rearing SYSTEMS

Mosquito mass rearing techniques, including racks, have improved significantly over the last few decades. However, we have designed/conceptualized a number of modifications to further optimize the space utilization and handling of mosquito rearing tools. Given the increase in demand for mosquito rearing facilities worldwide, we would be happy to develop a joint R&D proposal to prototype and test our and your ideas in close interaction. We are particularly interested in increasing the level of automation (filing, feeding, rinsing, refilling, etc.) of single racks and large facilities; we hold considerable experience in research projects at national and international levels.

INSECT FARMING Systems with Dry Substrate

For the production of mealworms and other insects in trays filled with dry feed / substrate, consider our cost- and space-effective Track & Rack farming system or stand-alone insect production trays.