UAV-Mounted AIR sampling Devices for Vials and Sorbent Tubes

VSI UAV-based Air Samplers. Measuring the gas composition, volatiles, particulate matter and/or isotopic signature of air provides critical information on water use, carbon balance, greenhouse gas emissions or pollutants in natural or managed ecosystems or urban environments. UAV based devices can contribute to improved monitoring of atmospheric background levels and air quality, as well as improved modelling of net surface-atmosphere fluxes, by extending the part of the lower troposphere that can be sampled. UAV thus also allow for sampling along vertical profiles in the lower boundary layer, and in remote areas, that would require expensive eddy flux towers or the use of balloons, or could not be monitored previosuly. There is thus scope for UAV-mounted sampling systems to contribute to improved monitoring of GHGs and air pollutant emissions, which is of utmost importance when dealing with mitigation measures or enforcement of environmental laws. To enable remote air sampling for extended user groups, we developed two drone-mountable air sampling systems to either collect:

- ambient, whole air into evacuated vials (AS-110), or

- use sorbent tubes of various types (AS-111) for sampling.

The products originate from cross-sectoral research projects ("Iso-Drone"). See Leitner et al. (2023) UAV-based sampling systems to analyse greenhouse gases and volatile organic compounds encompassing compound-specific stable isotope analysis, Atmos. Meas. Tech., 16, 513–527, https://doi.org/10.5194/amt-16-513-2023, for exemplary scientific use and proof of work of both air autosampler systems on unmanned aerial systems (UAS). Samplers can fit any medium-sized UAV with sufficient payload (ca. 1 or 1.2 kg, respectively) and 12V supply.

VSI AIR Samplers for UAV / Drone Deployment

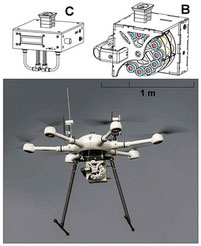

The air sampling systems for UAV consist of two complementary sampling devices for medium-sized UAVs

- VSI AS-110 Whole Air Sampler UAV (into evacuated glass vials; drawing B)

- VSI AS-111 Sorbent Tube Air Sampler UAV (drawing C)

See below for details.

UAV-Based AIr Sampler - Features

The VSI AS-110 Whole Air Vial Sampler UAV and AS-111 Multiple Sorbent Tube Air Sampler UAV allow sampling from up to 12 vials or tubes.

- Vial and tube dimensions are factory adjustable to suit your analytical requirements.

- Get more done and cover new areas and heights with worry-free, independent air sampling at preset locations or triggered manually.

- Easy to use and portable - simply mount the unit on UAVs for routine sampling.

- Easily retrieve vials and tubes at the end of flights, and load new vials/tubes for the next flight within minutes.

- Collect accurate samples with confidence, and prevent sample loss or contamination.

- Can be used almost anywhere and on all medium-sized UAVs with 12V supply.

- Sample ambient air and pollutants or monitor industrial emissions.

UAV-based Whole Air Sampling into Evacuated Vials - Specifications VSI AS-110

AS-110 UAV-based Whole Air Sampler. The whole-air sampler for UAVs weighs < 1 kg ( 200 x 200 x 200 mm) and can be loaded with up to 12 glass vials in a rotating barrel. The sample gas inlet is positioned at a vertical offset of 40 cm to the centre of the UAV rotor plane in order to minimise the impact of the airflow from the UAV rotors (Alvarado et al., 2017; Palomaki et al., 2017; Do et al., 2020; Zhou et al., 2018). PEEK tubing of 0.5 mm inner diameter (lenght of approx. 70 cm) is used to connect the downward-facing sample inlet (at the centre of the UAV rotor plane) to the gas inlet of the VSI AS-110 air sampler, which was mounted to the bottom of the UAV platform. The gas inlet consists of a G23 side port needle (Hamilton Bonaduz AG) mounted to a moving cantilever. At a sampling event the cantilever pushes the needle through the glass vial septa and thereby enables the evacuated vial to equilibrate with the surrounding environment, sucking in a gas sample of approx. 20 mL (equilibration time of 25 s). The dead volume of the transfer line is 100 µL. The gas sampler is triggered to gather a sample utilising a 5 V DC relay connected to a open-source autopilot. For example, the relay can be autonomously triggered with missions created using Mission Planner GCS; e.g. by approaching within 2 m of a designated point where the UAV is programmed to delay and gather a sample at the designated point for 25 s (to glass vials) or 600 s (to sorption tubes; see below). The UAV can subsequently move to the next sampling location or return and land. Air sample collection can alternatively be triggered manually, utilising the pilot's console transmitter. The whole air sampler is mounted underneath the UAV fuselage between the landing gear legs using a quick release dovetail mount; 12 V DC power was supplied to the VSI AS-110 sampler from the UAV.

See below for a short example video with the mounted air sampler flying next to a classical eddy tower.

UAV-mountable Air Sampler for Sorbent Tubes - Specifications VSI AS-111

AS-111 UAV-based Sorbent Tube Air Sampler. At the current configuration, the sorbent tube gas sampler for UAV can be loaded with four sorbent tubes (weight: 1200 g; dimensions: 180 x 155 x 130 mm (Lenght, Width, Height) with installed tubes). The sample gas inlet can be set with a manually adjustable pinch valve and maintained at 50 mL min−1 when e.g. using 6 mm thick Tenax GR packed sorbent tubes (see overview on sorbent tube types). All tubing is made out of 4 or 6-mm PTFE, and tube connections out of polyethylene terephthalate (PET) or metal. Passing the restriction valve at the sampler inlet, the gas flow is split in two using a Y connector and forwarded to the two inlet ports of an electric four-port gas distribution manifold. The gas manifold enables switching between different sampling modes, either loading all four tubes simultaneously, individually or allows for collecting subsequent duplicates. The sorbent tubes are installed at the outlets of the gas manifold using straight push-in connections. At the outlet of the four sorbent tubes, the gas flow is merged into two streams using a 90° push-in Y connector. Each stream then passes through a flow sensor, recording the actual flow rate. The gas streams are finally united and directed to the suction pump. To circumvent the non-regulated suction pressure of the pump, a tee piece is installed prior to the pump feed to equalise the different flow rates set at the restriction valve of the gas inlet. Thereby the exposure to pressure differentials resulting in altered flow readings, and the development of leaks and the overuse of sampler components is effectively prevented.

The VSI AS-111 sorbent tube sampler for UAV is equipped with a memory card, recording the actual flow rate, temperature, air pressure, humidity, the activated sample port number, and time over the sampling event. The gas sampler is triggered to gather a sample utilising a 5 V DC relay connected to an open-source autopilot. For example, the relay can be autonomously triggered with missions created (e.g. using Mission Planner GCS); e.g. by approaching within 2 m of a designated point. Here, the UAV can be programmed to delay and gather a sample for x seconds to sorption tubes. The UAV can subsequently fly to the next sampling point or height, or return and land. A sample can alternatively be collected manually, utilising the pilot's console transmitter. The sorbent tube sampler is mounted underneath the UAV fuselage between the landing gear legs using a quick release dovetail mount; 12 V DC power must be supplied to the VSI AS-111 sampler from the UAV.

The AS-111 sorbent system is able to carry sorbent tubes for a large range of air sampling purposes (see overview on sorption materials), for example the location and hight profiles of volatile emissions, pollen and particulate matter (PM2.5, PM10) concentrations. The sorbent sampling system is currently adapted to meet the demands of policing missions with heavy UAVs in the project C-SALS. Vienna Scientific is happy to contribute to the development of adapted sampling systems - meeting the air sampling needs of your research or environmental monitoring project.

UAV-based Air Sampling

Air sampling via UAV / drones possesses enormous advantages in regard to costs and flexibility. This is illustrated well by this image (and the video below), where an UAV, with the VSI AS-110 whole air sampler mounted, is effectively stirred to different sample locations / heights while "standard" measurements of air height profiles normally reguire a massive investment in flux tower infrastructures. UAV thus allow for easier and extended sampling along vertical profiles in the lower troposphere and access to remote locations. UAV systems with air samplers can thus contribute to improved monitoring of GHGs and air pollutant emissions, which is of utmost importance when dealing with mitigation measures, or monitoring of emission treasholds and subsequent enforcement of environmental laws. See below for example images and short videos - with the AS-110 whole air sampler mounted on an UAV.

ApPlication of UAV-based Air sampling for Keeling plot Analysis

- The carbon isotopic signature of CO2 in canopy air provides valuable information on the physiological processes underlying net biosphere-atmosphere CO2 exchange and has been used to study plant water use and to partition net CO2 exchange between assimilation and respiration. In most cases, a 'Keeling plot' approach is used, in which the carbon isotopic ratio of CO2 in canopy air is regressed on its inverse CO2 mixing ratio to determine the carbon isotopic signature of ecosystem-respired CO2. Continue reading

-

The 'Keeling plot' approach requires a precision in δ13C analysis of better than 0.1‰ for robust statistical analysis. To achieve this precision, large vials (1 L or 100 mL) were previously used. However, the size and cost of large vials limits the number of containers that can practically be transported and collected in the field. This, in turn, limits sample replication and statistical robustness. However, methods have been developed that allow the collection of a large number of samples, based on easy-to-use and inexpensive septum-capped 10 or 20 ml glass vials, which can then be analysed on a continuous-flow isotope ratio mass spectrometer (Révész & Landwehr, 2002) or similar. The study by Leitner et al. (2023) showed that our whole air autosampler systems on unmanned aerial systems (UAS) can provide high-quality isotopic air samples for Keeling plot analyses, allowing to expand the measurements to extended profiles of the troposphere and to cover larger and remote sample areas.

| References |

Air Sampling and Analysis with UAVs |

OPEN |

|

||

An automatic vial evacuator (VSI EV-101) to evacuate/reuse vials (incl. helium flushing and a strong vacuum pump) is available as option, allowing to easily prepare "fresh", effective vacuum tubes both in the lab (220V) and the field (12V) for immediate use in whole air sampling campaigns